roughing end mill cutter diagram

MACHINE SHOP PRACTICE S5 MECH 2015 53 17613 Helical Milling Operation Helical milling produces helical flutes or grooves on the periphery of a cylindrical or conical work piece. The most common type of rod mill is the overflow mill.

Two Flute End Mill Cutter Geometry Centre Cutting Type Download Scientific Diagram

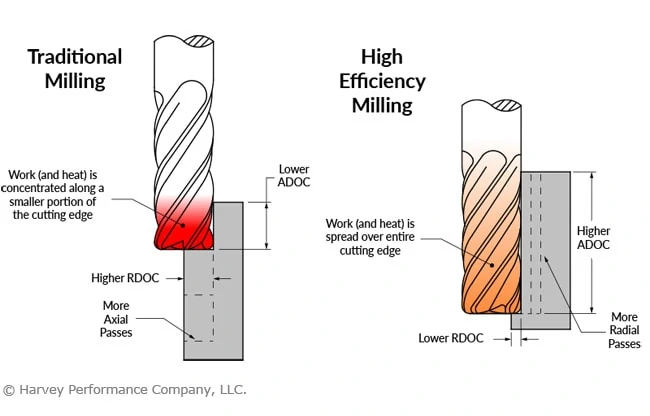

Up to 34 of the cutter diameter it doesnt matter which way you cut.

. Jira will be down for Maintenance on June 62022 from 900 AM - 2PM PT Monday400 PM - 900PM UTC Monday. 98 of products ordered ship from stock and deliver same or next day. Diagram of typical Bridgeport style milling machine head.

For the Subaru BLBP Liberty and BP Outback the EJ251 was replaced by the EJ252 engine. End mills middle row in image are those tools that have cutting teeth at one end as well as on the sides. Extramural research units of the South African Medical Research Council.

Führende Gear Grinding Technology von Reishauer. Subarus EJ251 and EJ252 were 25-litre horizontally-opposed or boxer four-cylinder petrol engines. G71 Rough Turning Cycle Overview.

The tooth design allows for little to no vibration but leaves a rougher. Cerca nel più grande indice di testi integrali mai esistito. The South African TB Vaccine Initiative SATVI which includes Mark Hatherill Director Tom Scriba Deputy Director and Elisa Nemes.

There are two typed of ball mills used. Roughing or finishing - Roughing means high feeds finishing means low feeds. Pocket Milling Another form of end milling used to mill shallow pockets into flat parts Figure e pocket milling.

Use a coarse-tooth milling cutter for roughing cuts and a finer-toothed milling cutter for light cuts and finishing operations. Surface Contouring Ball-nose cutter is. There is an increasing trend to employ SAG mills semiautogenous mills in place of secondary and tertiary crushing and primary grinding.

Precision and Genomic Medicine. Im Wörterbuch der Verzahnung finden sie alle Wälzschleif-Fachbegriffe in Deutsch und English. For Australia the EJ251 engine was first introduced in the Subaru BEBH Liberty in 1998 and subsequently offered in the BH Outback GDGG Impreza RS and Subaru SG Forester.

BibMe Free Bibliography Citation Maker - MLA APA Chicago Harvard. Three multi-investigator groups that operate principally in the TBHIV space. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

Imagine how a CAM program might work for the lathe. The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torusThey are usually made from high speed steel or cemented carbide and have one or. The cutter selection also depends upon tooth profile and their spacing.

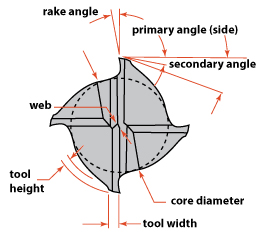

The cutter used for this operation is cylindrical type or end mill type. Diagram of an End Mill. The Wellcome Centre for Infectious Diseases Research in Africa CIDRI-Africa which includes Robert Wilkinson Director Graeme Meintjes Catherine Riou and Anna Coussens.

End Milling Cutter diameter is less than work width so a slot is cut into part Figure - c end milling. When cutting half the cutter diameter or less you should definitely climb mill assuming your machine has low or no backlash and it is safe to do so. Discover all the collections by Givenchy for women men kids and browse the maisons history and heritage.

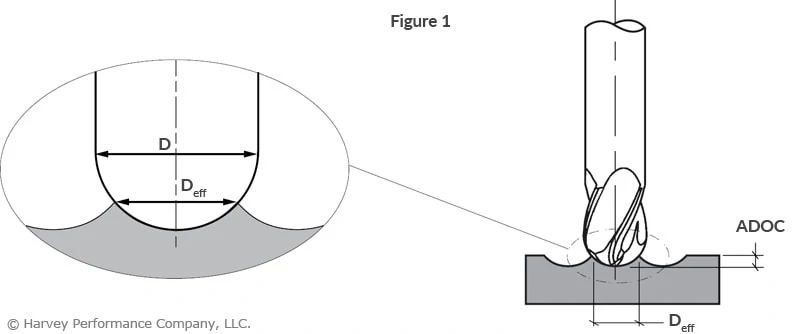

CoNLL17 Skipgram Terms - Free ebook download as Text File txt PDF File pdf or read book online for free. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. SAG mills rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants.

When cutting from 34 to 1x the cutter diameter you should prefer conventional milling. The RPM for a l2-inch-diameter end mill machining aluminum revolves at 2400 RPM and the feed rate should be 24 inches per minute. - -- --- ---- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- ----- -----.

McMaster-Carr is the complete source for your plant with over 700000 products. You draw the profile that you want to turn on a part push a button and out comes g-code that converts that profile into the right moves to cut the profile in multiple passes based on the depth of cut for each pass you specified.

ป กพ นในบอร ด 11v9 Resin Bond Grinding Wheel

Build A Tool Custom Special End Mill Cgs Tool Premium Solid Carbide End Mills

Basic Servo Hydraulic Press Drive Machine Tools Hydraulic Technology

End Milling And Peripheral Milling Download Scientific Diagram

Schematic Diagram Of The Side Milling Process Download Scientific Diagram

8 Ways You Re Killing Your End Mill In The Loupe

Solid Carbide End Milling Harvi I Te Four Flute End Mill For Roughing And Finishing Covering The Broadest Range Of Applications And Materials

End Mill An Overview Sciencedirect Topics

Cnc Programming Examples G91 Incremental Programming Tutorials Programming Dibujo Tecnico Ejercicios Tecnicas De Dibujo Electricidad Y Electronica

Cutting Forces In End Milling Download Scientific Diagram

Ball Nose Milling Strategy Guide In The Loupe

Basic End Mills Technical Information Msc Industrial Supply Co

End Mill An Overview Sciencedirect Topics

Basic End Mills Technical Information Msc Industrial Supply Co